Common roller bearings use cylinders of slightly greater length than diameter. Roller bearings typically have higher radial load capacity than ball bearings, but a lower capacity and higher friction under axial loads. If the inner and outer races are misaligned, the bearing capacity often drops quickly compared to either a ball bearing or a spherical roller bearing.

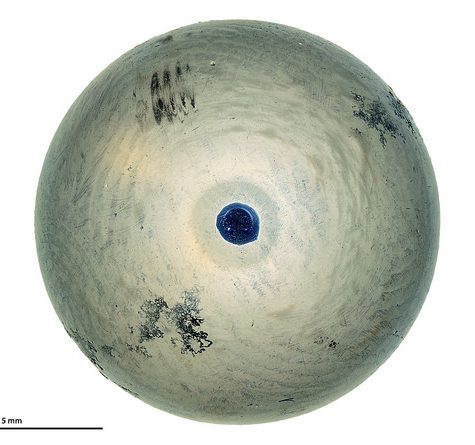

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axialloads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

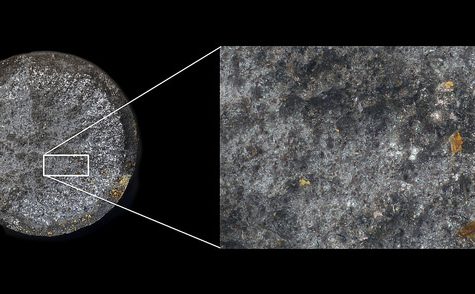

Metal testing is a process or procedure used to check composition of an unknown metallic substance. There are destructive processes and nondestructive processes. Metal testing can also include, determining the properties of newly forged metal alloys. With many chemical-property databases readily available, identification of unmarked pure,common metals can be a quick and easy process. Leaving the original sample in complete, re-usable condition. This type of testing is nondestructive. When working with alloys (forged mixtures) of metals however, to determine the exact composition, could result in the original sample being separated into its starting materials, then measured and calculated. After the components are known they can be looked up and matched to known alloys. The original sample would be destroyed in the process. This type of testing is destructive.

Metal testing is a process or procedure used to check composition of an unknown metallic substance. There are destructive processes and nondestructive processes. Metal testing can also include, determining the properties of newly forged metal alloys. With many chemical-property databases readily available, identification of unmarked pure,common metals can be a quick and easy process. Leaving the original sample in complete, re-usable condition. This type of testing is nondestructive. When working with alloys (forged mixtures) of metals however, to determine the exact composition, could result in the original sample being separated into its starting materials, then measured and calculated. After the components are known they can be looked up and matched to known alloys. The original sample would be destroyed in the process. This type of testing is destructive.

Metal testing is a process or procedure used to check composition of an unknown metallic substance. There are destructive processes and nondestructive processes. Metal testing can also include, determining the properties of newly forged metal alloys. With many chemical-property databases readily available, identification of unmarked pure,common metals can be a quick and easy process. Leaving the original sample in complete, re-usable condition. This type of testing is nondestructive. When working with alloys (forged mixtures) of metals however, to determine the exact composition, could result in the original sample being separated into its starting materials, then measured and calculated. After the components are known they can be looked up and matched to known alloys. The original sample would be destroyed in the process. This type of testing is destructive.

Metal testing is a process or procedure used to check composition of an unknown metallic substance. There are destructive processes and nondestructive processes. Metal testing can also include, determining the properties of newly forged metal alloys. With many chemical-property databases readily available, identification of unmarked pure,common metals can be a quick and easy process. Leaving the original sample in complete, re-usable condition. This type of testing is nondestructive. When working with alloys (forged mixtures) of metals however, to determine the exact composition, could result in the original sample being separated into its starting materials, then measured and calculated. After the components are known they can be looked up and matched to known alloys. The original sample would be destroyed in the process. This type of testing is destructive.

Metal testing is a process or procedure used to check composition of an unknown metallic substance. There are destructive processes and nondestructive processes. Metal testing can also include, determining the properties of newly forged metal alloys. With many chemical-property databases readily available, identification of unmarked pure,common metals can be a quick and easy process. Leaving the original sample in complete, re-usable condition. This type of testing is nondestructive. When working with alloys (forged mixtures) of metals however, to determine the exact composition, could result in the original sample being separated into its starting materials, then measured and calculated. After the components are known they can be looked up and matched to known alloys. The original sample would be destroyed in the process. This type of testing is destructive.

Metal testing is a process or procedure used to check composition of an unknown metallic substance. There are destructive processes and nondestructive processes. Metal testing can also include, determining the properties of newly forged metal alloys. With many chemical-property databases readily available, identification of unmarked pure,common metals can be a quick and easy process. Leaving the original sample in complete, re-usable condition. This type of testing is nondestructive. When working with alloys (forged mixtures) of metals however, to determine the exact composition, could result in the original sample being separated into its starting materials, then measured and calculated. After the components are known they can be looked up and matched to known alloys. The original sample would be destroyed in the process. This type of testing is destructive.

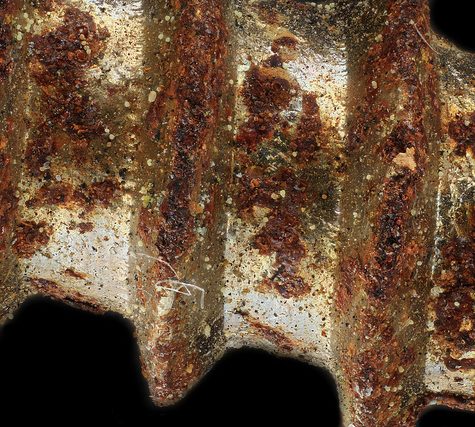

A screw is a type of fastener, sometimes similar to a bolt (see Differentiation between bolt and screw below), typically made of metal, and characterized by a helical ridge, known as a male thread (external thread) or just thread.